PRODUCTS

- High Voltage Transformers

- Switchmode Transformers

- Flyback Transformers

- Trigger Pulse Transformers

- Step Up/Down Transformers

- Power Transformers

- Toroidal Transformers

- Antennas and Air Coils

- Down Hole Applications

- DC Igniters

- High Current Inductors

- Custom Manufacturing

- Hydrogen Coils

- Control Transformers

- Inverter Transformers

- Low Profile (LPC) Transformers

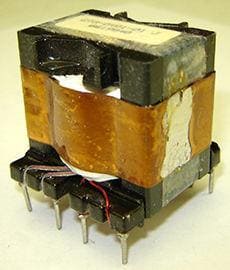

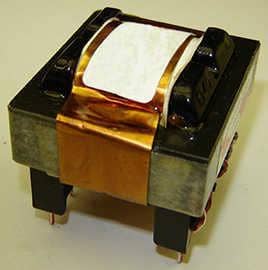

- Ferrite Transformer

- Pulse Transformers

- Single Phase Transformer

- Specialty Transformers

- Isolation Transformer

- Surface Mount Transformer

- Toroidal Inductor

- Air Core Inductors

- Ferrite Inductors

- Power Inductors

- Surface Mount Inductors

Quick Contact

How to Make a Step-up Transformer?

What is a Transformer?

The transformer is a static device that is used in electrical or electronic circuits to change the voltage in an Alternating Current (AC) electrical supply. It transforms electrical energy from one circuit to another with the help of mutual induction between the primary and secondary windings. Typically, the frequency of the input signal is not changed, but the voltage can be increased or decreased depending upon the need..

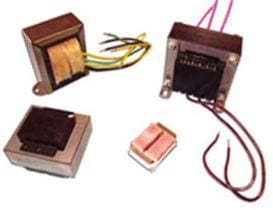

Types of Transformers

As mentioned above, there are two basic types of transformers:

- Step-up Transformer: A step-up transformer increases the output voltage in relation to the input voltage. In this type of transformer, the number of turns on the secondary winding is more than the number of turns on the primary winding.

-

Step-down Transformer:A step-down transformer decreases the output voltage in relation to the input voltage. This type of a transformer is opposite of the above, the number of turns on the secondary winding is less than the number of turns on the primary winding.

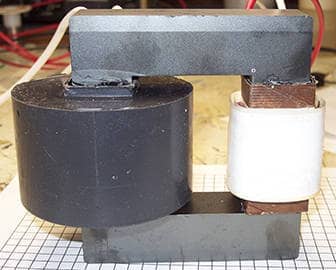

Parts of Transformer

Before beginning to build a step-up transformer, let us understand the main parts of a transformer:

- Primary Winding - constructed from magnet wire

- Magnetic Core – selected based off input signal power and frequency

- Secondary Winding – constructed from magnet wire

Things Required for Building a Very Basic Step-up Transformer

You will require the following components prior to initiating the construction process:

- Electrical insulating tape

- Coated copper wire (i.e. magnet wire)

- Core material (i.e. steel bolt can be used to represent a core)

- A resistive element (such as a light bulb)

- Alternating current power supply

Building an Electrical Step-up Transformer

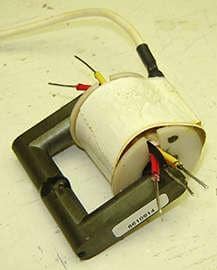

The following steps explain the process of building a step-up transformer in detail:

-

Use a large steel bolt as the transformer’s magnetic core. Test the bolt first for magnetization by holding it against a kitchen magnet. If the magnet sticks, the steel bolt is usable as a core.

-

Wrap the bolt with insulating tape to isolate the windings from the “core”. Cut the coated copper wire into two unequal lengths, and strip them at the ends. Using the same wire will help you ensure that the coil winding counts are comparable.

-

Wind the two copper wires several times (at least 12 turns) around the ends of the “core” (steel bolt). These wire coils will act as the primary and secondary windings of the transformer. Make sure the bare ends of the wires are kept free. Also, maintain a space between the primary and secondary windings. Secure with insulating tape.

-

Now, connect the bare ends of the secondary coil to the contact terminals of the resistive element (bulb). Make sure they don't touch each other at the bulb contacts, because a short will prevent the bulb from lighting. You can use electrical insulation tape to hold the wires in place if necessary.

-

Finally, connect the bare ends of the primary coil to an AC power supply. Selecting an AC power supply with a power switch, adjustable voltage setting and a fuse on the input will help provide safety and isolation from “the wall” power. Start with the AC power at its lowest level and steadily increase to see the brightness of the bulb change. The bulb should illuminate upon switching on the power supply. If not, check the connections and try again.

-

In case you smell burning, remove the primary coil ends from power supply immediately. However, this is an unlikely situation, since the transformer should provide enough resistance to prevent too high of a current to pass.

-

If you do smell burning, check if the cause of a short circuit is due to the contact between bare wires. Cover the bare wires with electrical insulation tape and try again.

-

Notice that the luminosity of the bulb will go up in the step-up configuration. Moreover, the transformer core will start functioning as an electromagnet. This can be checked by placing metallic objects against it.

Tip: For making a industrial step-up transformer, it is necessary that the secondary winding has more turns than the primary. Moreover, if you want the transformer to have twice the voltage and half the current at the secondary, then put twice as many turns into the secondary coil.

Related Products

Once the step-up configuration is successfully completed, try reversing the coil turn ratio. This will allow you to compare the functioning of the transformer in step-down versus step-up mode. You can also test both the configurations against different resistor loads.