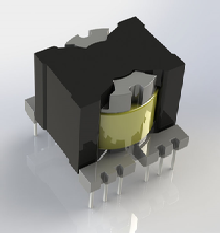

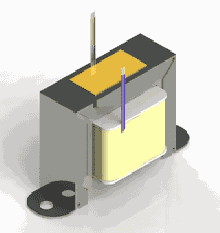

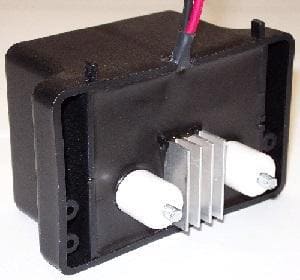

Pulse transformers are specially designed for high load applications, and are widely used across various industries for power distribution. They help in minimizing voltage drop, rise time, and pulse distortion. The pulse transformers can operate at high frequencies, and can transfer more power as compared to a normal transformer of the same size. Pulse transformers are widely used for low power circuits, high power switched mode power supplies, and signal transmission. Read this post to find out why pulse transformers are gaining a foothold in diverse industrial applications.

Advantages of using Pulse Transformers

Below are a few of the advantages of pulse transformers:

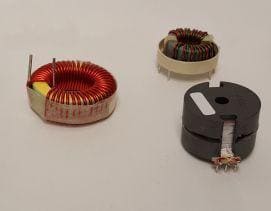

- High Energy Transfer: Pulse transformers are compact sized, and offer excellent repetitiveness, thereby offering short rise-time, wide pulse-width, and high energy transferring efficiency in most applications. Also, the leakage inductance is reduced due to the high permeability of its ferrite core, which allows high energy transfer within the transformer.

- Larger Number of Windings: Pulse transformers usually have more than two windings, which can be used to drive several transistors simultaneously. Due to this any kind of phase shifts or delays are minimized.

- Galvanic Isolation: A pulse transformer has a galvanic isolation between its windings, which eliminates the passing of stray currents. The property also allows the primary driving circuit, and the secondary driven circuit to operate at different potentials. The isolation can range between 4kV for electronic transformers of small sizes, and 200 KV for very high-power applications. The galvanic isolation property also fulfills the safety requirements, if one part is unsafe to touch due to passing of the high voltage.

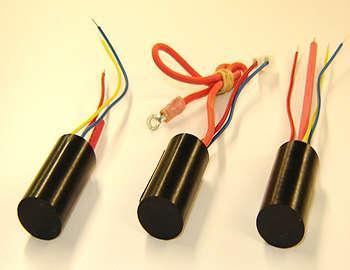

- Vacuum Potting: Pulse transformers are encapsulated with abrasive resins. These resins help control any kind of electric resistance or vibration within a transformer in a controlled atmosphere. This process is known as vacuum potting. Thermo-setting plastics or silicone rubber gels are also used for potting within the transformer. The potting compound also acts as an insulator. Also, this helps in minimizing the space requirements resulting in a better insulation.

The above-listed advantages make pulse transformers an energy efficient device making it prominent in various industrial units. If you are planning to buy one of these pulse transformers for your industrial applications, you can always depend on top-notch industrial expert like Custom Coils. The company manufactures a comprehensive range of pulse transformer as per the industrial demands. For more information please click here.