PRODUCTS

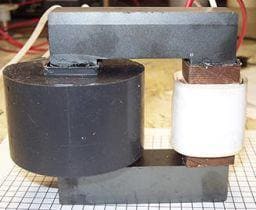

- High Voltage Transformers

- Switchmode Transformers

- Flyback Transformers

- Trigger Pulse Transformers

- Step Up/Down Transformers

- Power Transformers

- Toroidal Transformers

- Antennas and Air Coils

- Down Hole Applications

- DC Igniters

- High Current Inductors

- Custom Manufacturing

- Hydrogen Coils

- Control Transformers

- Inverter Transformers

- Low Profile (LPC) Transformers

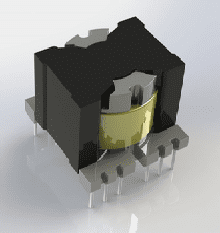

- Ferrite Transformer

- Pulse Transformers

- Single Phase Transformer

- Specialty Transformers

- Isolation Transformer

- Surface Mount Transformer

- Toroidal Inductor

- Air Core Inductors

- Ferrite Inductors

- Power Inductors

- Surface Mount Inductors

Quick Contact

How to Install a Large Power Transformer – Part IV

In previous posts, we had elaborated on transformer oil preparation and installation of gaskets, bushings, conservator tank, breather and explosion vents. In this post, we will discuss installation of Buchholz relay, temperature indicators, cooling equipment, and load tap changers. We will provide information on grounding the transformer and final installation.

- Fitthe Buchholz Relay to the Transformer: The Buchholz relay oil container is connected between the pipe work of the conservator tank and the main transformer tank. The relay should only be mounted after the transformer oil level is above the tank cover. If a gas release pipe is provided, it should be fitted at the relay’s top pocket, which should be opened. If the gas release pipe is not provided then the top pockets should be closed and screwed tightly.

- Install the Temperature Indicator: There are two indicators that need to be installed in the transformer - the Oil Temperature Indicator (OTI), and the Winding Temperature Indicator (WTI). They should be fitted in the transformer’s Marshalling kiosk. Before installation, the indicators should be checked for proper calibration. Thermometer bulbs should be inserted into the pockets of the transformer’s top cover. The OTI and WTI pockets should be filled with transformer oil when inserting the bulbs.

- Install the Radiator Cooling Units: The radiator units should be installed on the main body of the transformer using industrial gaskets. After this, the radiators should be filled with transformer oil and the interconnecting valves between the radiator and the transformer tank should be opened. Also, the cooling fans and oil circulating pumps should be installed. The wiring should be done according to the transformer drawings.

- Fitting of On Load Tap Changer: The on load tap changer is to be fitted onto the tank and its insulation resistance value should be measured. Once this has been completed, the lead from the tap changer should be connected to the terminal board tightly.

- Perform the Transformer Grounding Process: The main tank of the transformer should be earthed at multiple points. The grounding connection should have several cross-sections to carry a fault current for at least 30 seconds. All the transformer components, including the fans, oil pumps, and marshalling kiosk should be properly grounded.

- Complete Pre-Installation Work: After all the previous steps have been completed, only the minor but important tasks should be completed. These include setting the relays, and wiring trip contacts, alarms, and accessories to the marshalling kiosk. Once these are done, the transformer can be cleared for installation and commissioning.

Related Products

The transformer setup and installation process requires immense knowledge of all the components and requires immense attention to detail. The purpose of these how to article is to help customers understand the various steps involved in large transformer installation. It is always advisable to contact the manufacturer who can provide setup and installation services. This will help you comission the transformer quickly and efficiently. The transformer manufacturer can also provide suggestions on different components and safety procedures.