PRODUCTS

- High Voltage Transformers

- Switchmode Transformers

- Flyback Transformers

- Trigger Pulse Transformers

- Step Up/Down Transformers

- Power Transformers

- Toroidal Transformers

- Antennas and Air Coils

- Down Hole Applications

- DC Igniters

- High Current Inductors

- Custom Manufacturing

- Hydrogen Coils

- Control Transformers

- Inverter Transformers

- Low Profile (LPC) Transformers

- Ferrite Transformer

- Pulse Transformers

- Single Phase Transformer

- Specialty Transformers

- Isolation Transformer

- Surface Mount Transformer

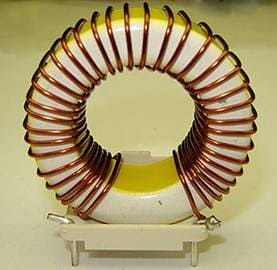

- Toroidal Inductor

- Air Core Inductors

- Ferrite Inductors

- Power Inductors

- Surface Mount Inductors

Quick Contact

How to Install a Large Power Transformer–Part II

In the previous post, we had discussed about the importance of transformer installation. We had also discussed the various pre-installation processes and best practices. In this post, we shall cover how to prepare the site and location for installing a power transformer.

These steps below describe points regarding the transformer’s foundation, and transformer cooling methods.

Site Preparation Steps

These steps below describe points regarding the transformer’s foundation, and transformer cooling methods.

- Create the Foundation: Generally, power transformers do not require any special types of foundation. However, it should be strong enough to carry the transformer’s weight. The foundation should be created in an area where technicians and engineers will have easy access to indicators and/or protection devices. These can include valves, thermometers, oil gauges, diaphragm plates, etc. Optimum clearance areas should also be provided for all live electrical components of the transformer.

-

Set up the Cooling Methods: Power transformers generate immense heat during operation. Hence, there is a need for ventilation or cooling mechanisms to be set up. This step can be performed in a few ways.

-

Outdoor Ventilation:

- If the transformer is designed as an Oil Natural Air Natural type, a good amount of free space should be kept around the transformer to allow for natural air circulation.

-

Indoor Ventilation:

- When the transformer is installed indoors, the room should be well ventilated with an appropriate number of air inlets and outlets.

- The inlets should be designed close to the floor, while the outlets should be close to the ceiling.

- If natural air circulation is limited or not possible, you can also use exhaust fans to create forced ventilation.

-

Outdoor Ventilation:

-

Installing the Wheels and Rollers: Wheels and rollers are installed onto transformers to allow them to move between short distances. There are certain points that need to be kept in mind if adding these components.

- If rollers are installed onto the transformer base, then a system of tracks or rails should be connected to the foundation.

- Use the track system to lock the rollers in place. This helps prevent any accidental movement of the transformer, especially during natural disasters.

- If wheels are not installed onto the base, then you need to install concrete plinths with bearing plates. The plinths need to be of appropriate size and weight to support the transformer.

Site Preparation Best Practices

As with pre-installation, there are certain points that need to be kept in mind to ensure comprehensive and long-lasting transformer site preparation.

- The foundation should be designed such that no water accumulates at the base of the transformer.

- Use bituminous compounds such as cretex to prevent water accumulation between the plinth and base.

- Ensure that you drain all the oil that will come out of the transformer. You can have oil drainage facilities to accomplish this. Oil drainage systems will prevent any kind of fire hazard. This point is very important for large power transformers.

Related Products

By following the above steps, you can ensure that the foundation created for the transformer is strong, safe, and will support the transformer during operation. In the next post, we will be focusing on oil preparation during transformer installation.